Improving your Data Processes Saves Time & Money

September 12, 2022

Don’t let your Bottom Line Lose its Luster

Case Study – Retail & Manufacturing

Improving your data processes saves you time and money. After implementing solutions from More4apps, which are simple yet effective, out-of-the-box solutions, James Avery Artisan Jewelry saved an estimated $840K annually.

Continue reading and learn how to improve your data processes so your bottom line doesn’t lose its luster.

The Client

James Avery Artisan Jewelry is a family-owned company that designs, manufactures, and sells primarily Christian-themed pieces.

The company was started by James Avery in 1954 in Kerrville, Texas out of his mother-in-law’s two-car garage with a capital of about $250.

Since that time, James Avery Artisan Jewelry has opened 50 stores and five manufacturing plants throughout North America.

The company uses a vertically integrated business model, which means teams are responsible for data from the purchase of raw materials to finished products.

Manual Entry is a Slow, Daunting Task that Leads to Errors

Before 2013, James Avery introduced roughly 300 jewelry pieces per year. The sales growth and vast product range meant coordinating over 87,000 items, 38,000 Bill of Materials (up to 8 levels), and 13,000 routings with 140+ operations for the manufacturing process.

However, the increased product range meant that the process of manually keying data was no longer viable. Manual entry was prone to errors and monopolized users’ time.

Furthermore, the manual entry took even longer and required a lot of navigation through the various Oracle E-Business Suite forms.

Data Bottlenecks

Save Time & Money when you Improve your Data Processes

Case Study

Don’t let your Bottom Line Lose its Luster

Like many companies, James Avery runs a continuous improvement program; however, data entry can slow or stop that process.

The James Avery improvement program consists of the following steps:

- Define the problem

- Develop a plan

- Implementation

- Review performance

Identifying areas of improvement led to implementing further changes. With manufacturing facilities opening throughout the US, James Avery understood the company was growing, and it needed to remove data bottlenecks to continue its growth.

The biggest drivers behind James Avery’s changes include:

- Competing responsibilities for functional users

- Standardized Bill of Materials set-up

- Improved Bill of Materials data accuracy

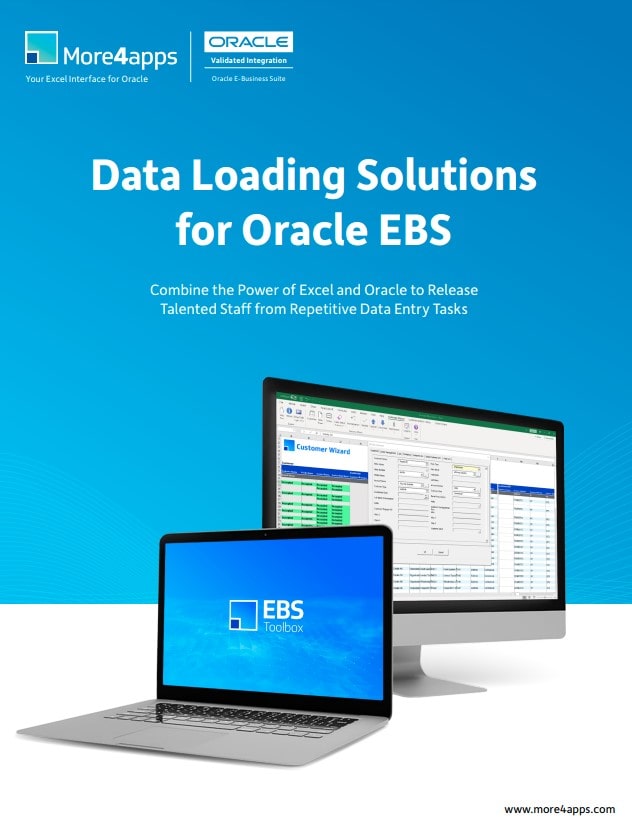

The Data Loading Solution for your Oracle ERP

After testing More4apps tools and receiving final approval from the company’s end-users, the tool was purchased and rolled out to production.

The introduction of the More4apps tools enabled James Avery to save an estimated $840,000 per year, update routings for over 20,000 finished products with a savings of $6,000, over 5,000 sub-assemblies in 4 organizations increasing inventory accuracy by 30%, and update inventory categories for demand forecasting on 18,000 items.

James Avery also introduced a min.-max. planning for 400 supply items and changed supply sub-inventories for over 20,000 finished products.

The company increased its ability to introduce new items from 300 to over 700 annually.

Before implementing More4apps tools, it took the jewelry company an average of 6 hours to set up finished products. Now, with the More4apps solutions embedded in its processes, the set up has improved by 600%.

“The uptake of the Wizards by my team has been amazing. They are simple to use, and we are using them on a daily basis. Issues such as updating the WIP supply type on Bill of Materials are handled in minutes rather than hours. Ultimately updating item categories is now a simple process. Data improvements are so vast; that other improvement programs, such as Cycle Counting, have been introduced to our 70 retail stores.”

– Joseph Reif, Production Scheduler, James Avery Artisan Jewelry

Additional Resources

Visit our Resource Library for additional materials or connect with an expert today!